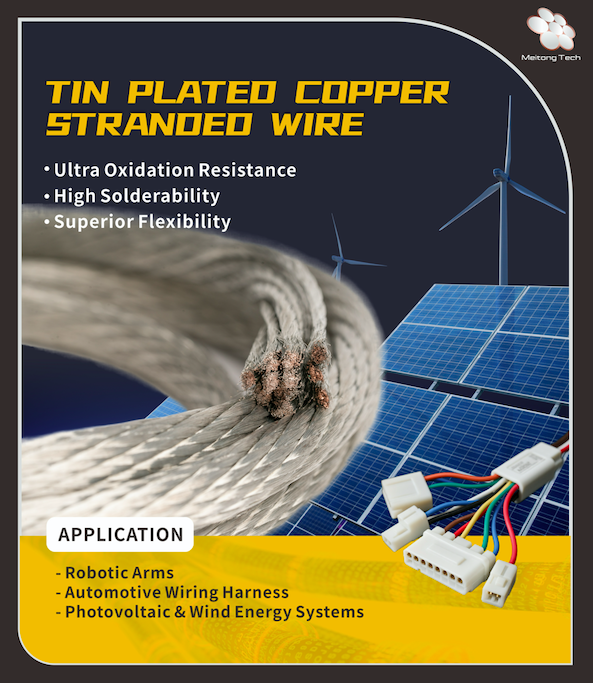

Tin - Plated Copper Stranded Wire, also known as Tinned Copper, is a high - performance electrical conductor with excellent properties. Its tin - plated surface provides enhanced corrosion resistance, ensuring long - term stability in various applications.

In robotics, the need for flexible and reliable wiring is crucial. Our tinned copper stranded wire can withstand the repeated bending and movement of robotic arms, ensuring continuous and stable signal and power transmission.

For soft connection applications, this wire offers the necessary flexibility and conductivity. It can be easily shaped and connected, providing a reliable electrical path in devices where movement or vibration is involved.

In military and medical fields, high - reliability and safety are paramount. The tinned copper stranded wire meets the strict requirements of these industries, withstanding harsh environments and ensuring accurate signal transmission in medical devices and reliable power supply in military equipment.

Battery systems require efficient and durable conductors. Our tinned copper wire can handle the high - current demands of battery cables, with its corrosion - resistant tin plating protecting against battery acid and other corrosive substances.

Automotive wiring harnesses need to endure high temperatures, vibrations, and mechanical stress. The tinned copper stranded wire provides excellent conductivity and durability, contributing to the reliable operation of automotive electrical systems.

Specification and Technology date | ||||

Section area (mm²) | Structure (number/mm) | Resistance (Ω/km)max | Tensile Strength (Mpa) | Elongation |

0.60/0.50 | 19/0.20 | 42.20 | 100-150 | 1-25 |

0.75 | 19/0.23 | 34.18 | ||

1.00 | 19/0.26 | 26.75 | ||

1.50 | 19/0.32 | 17.65 | ||

2.00 | 19/0.36 | 13.95 | ||

2.50 | 19/0.41 | 10.32 | ||

3.00 | 19/0.47 | 8.32 | ||

4.00 | 19/0.53 | 6.48 | ||

5.00 | 19/0.59 | 5.23 | ||

8.00 | 19/0.73 | 3.42 | ||

10.00 | 19/0.82 | 2.7 | ||

15.00 | 19/1.01 | 1.75 | ||

20-400 | All technology data and structure are complied customer's request | |||

• Improved Oxidation Resistance – Ideal for long-term applications in marine or tropical environments

• High Solderability – Tin coating allows easy and clean soldering

• Flexibility – Suitable for high-flex applications, including cable harnesses and robotic arms

• Wide Temperature Range – Performs reliably in environments up to 150°C

• Long Shelf Life – Resists aging compared to bare copper

Custom-Solutions Available

Our engineering team offers full OEM/ODM support, including:

• Customized plating thickness

• Special strand constructions

• Specific resistance and tensile targets

• Insulation & shielding options

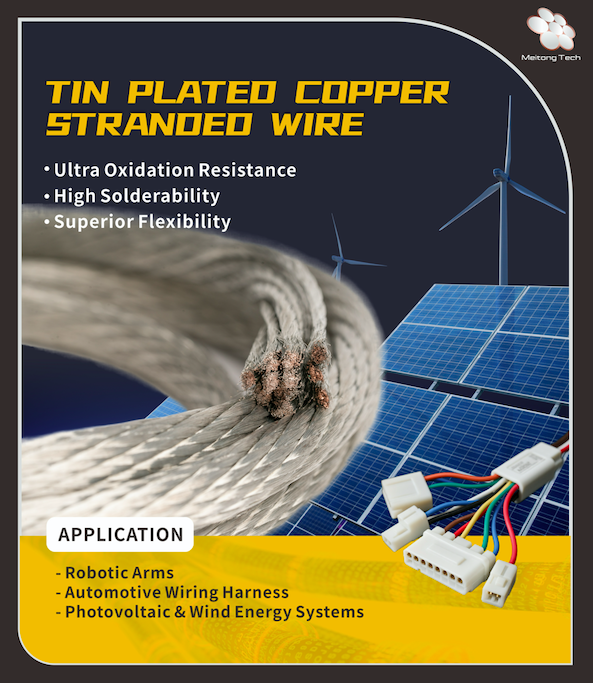

Tin - Plated Copper Stranded Wire, also known as Tinned Copper, is a high - performance electrical conductor with excellent properties. Its tin - plated surface provides enhanced corrosion resistance, ensuring long - term stability in various applications.

In robotics, the need for flexible and reliable wiring is crucial. Our tinned copper stranded wire can withstand the repeated bending and movement of robotic arms, ensuring continuous and stable signal and power transmission.

For soft connection applications, this wire offers the necessary flexibility and conductivity. It can be easily shaped and connected, providing a reliable electrical path in devices where movement or vibration is involved.

In military and medical fields, high - reliability and safety are paramount. The tinned copper stranded wire meets the strict requirements of these industries, withstanding harsh environments and ensuring accurate signal transmission in medical devices and reliable power supply in military equipment.

Battery systems require efficient and durable conductors. Our tinned copper wire can handle the high - current demands of battery cables, with its corrosion - resistant tin plating protecting against battery acid and other corrosive substances.

Automotive wiring harnesses need to endure high temperatures, vibrations, and mechanical stress. The tinned copper stranded wire provides excellent conductivity and durability, contributing to the reliable operation of automotive electrical systems.

Specification and Technology date | ||||

Section area (mm²) | Structure (number/mm) | Resistance (Ω/km)max | Tensile Strength (Mpa) | Elongation |

0.60/0.50 | 19/0.20 | 42.20 | 100-150 | 1-25 |

0.75 | 19/0.23 | 34.18 | ||

1.00 | 19/0.26 | 26.75 | ||

1.50 | 19/0.32 | 17.65 | ||

2.00 | 19/0.36 | 13.95 | ||

2.50 | 19/0.41 | 10.32 | ||

3.00 | 19/0.47 | 8.32 | ||

4.00 | 19/0.53 | 6.48 | ||

5.00 | 19/0.59 | 5.23 | ||

8.00 | 19/0.73 | 3.42 | ||

10.00 | 19/0.82 | 2.7 | ||

15.00 | 19/1.01 | 1.75 | ||

20-400 | All technology data and structure are complied customer's request | |||

• Improved Oxidation Resistance – Ideal for long-term applications in marine or tropical environments

• High Solderability – Tin coating allows easy and clean soldering

• Flexibility – Suitable for high-flex applications, including cable harnesses and robotic arms

• Wide Temperature Range – Performs reliably in environments up to 150°C

• Long Shelf Life – Resists aging compared to bare copper

Custom-Solutions Available

Our engineering team offers full OEM/ODM support, including:

• Customized plating thickness

• Special strand constructions

• Specific resistance and tensile targets

• Insulation & shielding options